Environmental

CEI performs a broad range of environmental services, including civil engineering services related to hazardous waste remediation, water resources investigations and program implementation; and ecological projects such as wetlands restorations among others. The most important aspect of our work in these areas is our rigorous scientific approach combined with pragmatic, green solutions and high attention to detail.

These services include:

- Preparation of plans and specs for hazardous waste remediation

- Water resources investigations and program implementation

- Wetlands restorations

EXPERIENCE

Investigation & Remediation Preparation

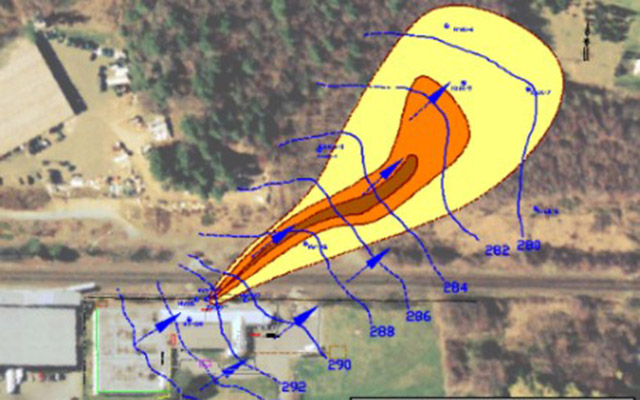

GROUNDWATER REMEDIATION

Preparing plans and specs for the remediation of chlorinated solvents from a metals processing facility including a DNAPL Plume. VIEW WORK

Water Resources

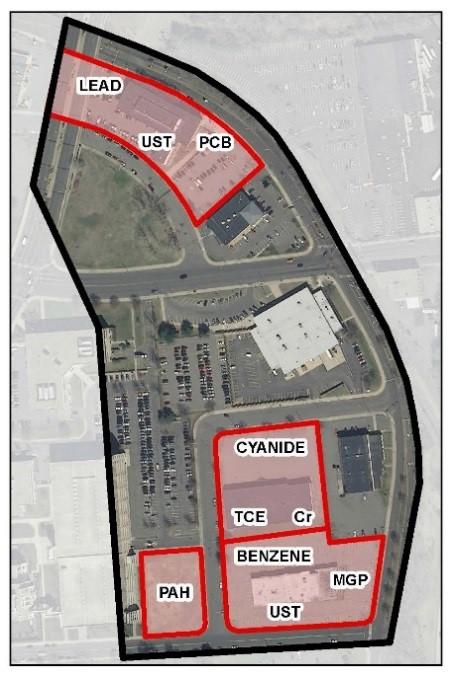

City of New Britain, CT

CEI was retained by the City of New Britain to perform various Environmental Assessments, Demolition... VIEW WORK

Ecological

Pennichuck Water Works

For nearly two decades, CEI has been assisting Pennichuck Water Works with its Watershed Restoration efforts, beginning... VIEW WORK

“CEI’s responsiveness and wide variety of services has consistently saved me time and money. I trust their people to be thorough, honest and to give me solid advice. I know I can call CEI anytime for professional engineering and environmental services - no matter what the issue.”

“CEI’s responsiveness and wide variety of services has consistently saved me time and money. I trust their people to be thorough, honest and to give me solid advice. I know I can call CEI anytime for professional engineering and environme...

“CEI`s geotechnical analysis was thorough and extensive, they provided us with cost effective options to ensure the long term integrity of our facility.”

“CEI`s geotechnical analysis was thorough and extensive, they provided us with cost effective options to ensure the long term integrity of our facility.”

“CEI was able to expedite this important project by working closely with MA Highway officials. We were greatly pleased with their efforts and the new access.”

“CEI was able to expedite this important project by working closely with MA Highway officials. We were greatly pleased with their efforts and the new access.”

“CEI has been great to me. A very team oriented atmosphere where the voices of newer engineers is still heard and advancement is based on merit.”

“CEI has been great to me. A very team oriented atmosphere where the voices of newer engineers is still heard and advancement is based on merit.”

“CEI has been great to me. A very team oriented atmosphere where the voices of newer engineers is still heard and advancement is based on merit.”

“CEI has been great to me. A very team oriented atmosphere where the voices of newer engineers is still heard and advancement is based on merit.”